Railway Vehicle Testing

Electrical Safety and Function Testing for all Applications in Railway Technology.

Galleys

SCHLEICH offers test solutions for intermediate and end of line inspection of commercial kitchens, hotel kitchens and household appliances for the entire production process of the devices.From testing individual components tot he end of line test of entire galleys, we offer the full range of safety and quality testing methods from one source.

Test Methods

- PE/GB-resistance

- insulation resistance

- high voltage AC

- high voltage DC

- leakage current

- ohmic resistance Ω

- current consumption

- power consumption

- electric functionality and parameters

- physical parameters including temperature, pressure, speed, vibration, …

- and more

High Voltage Equipment

SCHLEICH offers test solutions for intermediate and end of line inspection of Insulators, high voltage cables and for and for components operated under high voltage in general.From testing individual components to end of line testing of a full-fledged high voltage system, we offer the full range of safety and quality testing methods from one source.

Test methods

- high voltage AC

- leakage current

- high voltage DC

- insulation resistance

- dielectric strength

- and more

PE/GB Test

SCHLEICH offers test solutions for intermediate and end of line inspection of safe low-resistance PE/GB-connections between all components. From testing individual components to the end of line test of the PE/GB-connection between wagon and rail, we offer the full range of safety and quality testing methods from one source.

Test methods

- PE/GB-resistance

- high test current

- fully assembled adapter sets for wheel and rail

- and more

Winding Materials

SCHLEICH offers test solutions for every step of the production of electric winding materials.From testing the copper wires through professional winding testing to the complete transformer …You can choose from a variety of test methods for safety- and quality checks.

Test methods

- surge voltage up to 50 kV

- partial discharge with surge voltage test

- DAR – dielectric absorption ratio

- PI – polarization index

- high voltage AC

- partial discharge with high voltage

- high voltage DC

- insulation resistance

- winding resistance

- inductance

- capacitance

- circuit arrangement

- voltage ratio

- and more

Air Conditioning Systems

SCHLEICH offers test solutions for intermediate and end of line inspection of commercial air conditioning systems for the entire production process of the devices. From testing individual components to end of line testing of full-fledged cooling-, heating- and air conditioning systems, we offer the full range of safety and quality testing methods from one source.

Test methods

- PE/GB-resistance

- insulation resistance

- high voltage AC

- high voltage DC

- leakage current

- ohmic resistance Ω

- current consumption

- power consumption

- electric functionality and parameters

- physical parameters including temperature, pressure, speed, vibration, …

- and more

Whether you are looking for a single test device or a large-scale complex end of line (EOL) test stand with a wide range of attachments, SCHLEICH is at your side. In addition to reliable testing technology and MES data exchange (Manufacturing Execution System), the international networking of testing and database systems, such as SAP®, is becoming increasingly important.

Traction Motors

SCHLEICH offers test solutions for every step of the production of electric machines. From testing the copper wires through professional winding testing to the complete motor … You can choose from a variety of test methods for safety- and quality checks.

Winding testing of stators and rotors

- surge voltage up to 50 kV

- partial discharge with surge voltage test

- insulation resistance

- high voltage AC

- partial discharge with high voltage AC test

- high voltage DC

- winding resistance

- inductance

- capacitance

- rotary field

- and more...

Motor testing

- safety

- function

- rotary encoder testing and -adjustment

- no-load and load operation

- torque/rpm

- direction of rotation

- vibration

- leakage

- continuous engine operation

- temperature test

- EOL

- and more

Electric Train Supply (ETS)

SCHLEICH offers test solutions for electric train supplies (ETS). Fully automated output testing for ETS-voltages (AC/DC) in accordance with RIC-conventions following safety testing and including a subsequent test result documentation.

Test methods

- insulation resistance

- high voltage AC

- high voltage DC

- power, standby power AC/DC

- electric function AC/DC

- power consumption AC/DC

- and more

SCHLEICH has supplied hundreds of test devices to companies in the railway supply industry. Reducing the vehicle service turnaround time is an essential target in LEAN management. Speedy, systematic and fully documented inspection of components relating to the electric train supply makes sure this requirement is met. As an additional feature, a safety test between carriage and electric train supply is performed.

Test results can be stored with a vehicle’s UIC-wagon number. With certain database technologies as a prerequisite, these results can be accessed in multiple service centers.

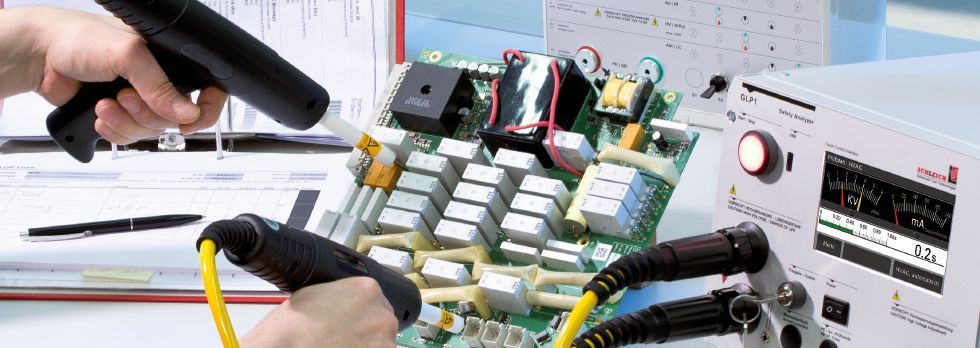

Power Electronics – Inverter

SCHLEICH offers test solutions for power electronics for driving electric machines. Inverter and drive form the central unit of the rail vehicle. These components are often tested as one or individually. You can choose from a variety of test methods for safety- and quality checks.

Inverter testing

- safety

- function

- limiting conditions

- peak currents

- switching off

- PWM

- power losses

- communication with the control unit

- leakage

- EOL

- and more

Electric Components

Test solutions for electric components of various types. We are dedicated to designing tailor-made solutions for all our customers.

SCHLEICH develops, engineers and manufactures single testing devices and automated testing systems precisely to your specifications.

In-depth consultation before the start of a project and the in-house development of the entire customer-specific system lead to a tailor-made configuration of hardware, software and mechanical adaptation. Whether you require individually designed test object molds or custom designed contactings – we will plan and build a turnkey solution for you – from the initial idea to the final installation.

Being your partner in a project, you can rely on our many decades of experience in project management. Additionally, we bring along our logistical infrastructure, PPS-controlled project support and guarantee that all the technologies used are always state of the art.

We look forward to talking to you. For more information, please contact us.

Test methods

Together we can configure your testing solution from a selection of 30 different test methods. Upon request we also regularly develop entirely new test methods.

SCHLEICH offers extensive expertise from designing and engineering thousands of custom-built test devices.

Lighting

Test solutions for inspection of lights and luminaries. From programming, adjustment and testing of individual control modules to complete lighting systems …

You can choose from a variety of test methods for safety- and quality checks.

Test methods

- PE/GB-resistance

- insulation resistance

- high voltage AC

- high voltage DC

- current input

- power, standby power

- leakage current

- electric function

- power consumption

- applying different Bus-systems for dimming , e.g. DALI …

- luminosity / brightness

- luminous color

- light distribution

- inspection with cameras

- communication interface with the control electronics

- control gear test

- “flashing“ the control gear

- adjustment of the control gear

- and more

SCHLEICH offers expertise gained from supplying thousands of test devices to the lighting industry.

The radical change from conventional lighting technologies to LEDs and the accompanying new functionalities are particularly evident in railway vehicles.

Auxiliary Drives

SCHLEICH offers test solutions for every step of the production of electric machines. From testing the copper wires through professional winding testing to the complete motor … You can choose from a variety of test methods for safety- and quality checks.

Winding testing of stators and rotors

- surge voltage up to 50 kV

- partial discharge with surge voltage test

- insulation resistance

- high voltage AC

- partial discharge with high voltage AC test

- high voltage DC

- ohmic resistance Ω

- inductance

- capacitance

- rotary field

- and more

Cable Harnesses

SCHLEICH offers test solutions for a wide range of types of cable harnesses. You can choose from a variety of test methods for safety- and quality checks.

Cable harness- / plug-in connector testing

- insulation resistance between the individual leads

- high voltage endurance between the individual leads

- continuity or line resistance

- polarity reversal between beginnings and ends of leads

- fully automated switch-over matrix between the individual leads

- switch-over matrix up to 50 kV high voltage testing

- plug-in connectors

- and more

SCHLEICH offers extensive expertise in automated testing of cable harnesses, particularly in combination with safety tests and at very high test voltages.

Motor Diagnostic Systems is at your side. Whether you are looking for a “basic” no-load test stand or a large-scale load test stand that includes a wide range of attachments. Many manufacturers of standardized and specialty motors worldwide rely on our testing technology. In addition to reliable testing technology and MES data exchange (Manufacturing Execution System), the international networking of testing and database systems, such as SAP®, is becoming increasingly important. From laboratory testing equipment for research and development to fully automated testing systems, Motor Diagnostic Systems is your one-stop shop.

All key aspects of expertise remain in the hands of SCHLEICH.

Our test systems are not created by simply combining off-the-shelf standard components. Each individual part is SCHLEICH know-how and is developed and manufactured in Hemer by our own team of experts.

Test devices and test systems

GLP3 | Class-leading testing technology unlimited.

The TOP class of testing and measuring technology for safety and functional testing.

- „All in one”

- Safety & functional testing devices

- For complex projects

- For complex automation

- For the highest demands

- Can be combined modularly from over 30 test methods

- Up to 350 test connections

- Switch matrices for all types of test methods

- PLe, SIL3, Cat4 safety circuit

- Windows 10®

- network

- Protocol & label printing

- Industry 4.0

- Interfaces to MES, ERP, SPS …

GLP3-M | Electric motor testing - EOL, series and laboratory

Test benches for functional and safety testing of all types of engines.

- asynchronous motors

- synchronous motors

- stepper motors

- BLDC

- DC motors…

- engine attachments

- Brake

- temperature sensor

- additional heating

- Ventilator

- Encoder, Resolver, Multiturngeber …

- Interfaces for automation such as PROFINET, EtherCAT, TCP/IP ...

- Interfaces to various ERP and MES systems ...