Schleich Test Technologies

High Voltage AC

Everything you always wanted to know about high voltage.

The high-voltage test (also called “HV test”, “hi pot” or “HiPot” worldwide) is one of the most important and meaningful test methods of all. It mercilessly uncovers insulation faults. That is why it can be found in almost all test regulations (e.g. VDE, EN, IEC, UL ...).

Why is the high-voltage test so important?

Washing machine, electric motor, lamp... these and almost all other electrical products and electrical systems can only be operated safely if they have high electrical insulation strength.

In the worst-case scenario, poor insulation can lead to electrical accidents resulting in serious injury or death, or to significant product damage.

With the high-voltage test, you determine the insulation quality and dielectric strength of your test object. Electrical products are checked with test voltages of typically up to 6,000 V.

In order to cover almost all areas of high-voltage testing, SCHLEICH supplies high-voltage testing devices from 3,000 to 100,000 V based on a very extensive range.

Where is the test object tested?

The test is between all current-carrying conductors and from current-carrying conductors to the housing.

Doesn't that also work with an insulation resistance test?

In principle yes, since the insulation resistance test is carried out between the same test points as a high-voltage test. However, significantly higher test voltages are used in the high-voltage test - a real endurance test for every test object!

In addition, the high-voltage test with AC voltage places particular stress on the test object. This hard quality analysis reliably reveals insulation weaknesses.

What errors does the high-voltage test reveal?

- Insulation distances too small

- Poor dielectric strength

- Insulation weaknesses between any electrical conductors to the protective conductor / device housing

- Poor insulation between the electrical conductors

- Poor insulation at air and creepage distances

- High-energy and low-energy punches

- Micro Discharges that can only spread to damage later in operation

What are the good/bad criteria?

The assessment of the high-voltage test is always based on the current flowing between the two high-voltage poles. The current is also often referred to as leakage current or leakage current. It must not exceed an adjustable limit. If it exceeds the limit, there is an insulation weakness.

High voltage test with AC or DC?

Whether the test voltage can be AC or DC depends on the standard for the product under test. It is often permissible to test with DC as well. For this purpose, the test voltage must be increased by 1.5 times the AC test voltage. At first glance, this seems to be significantly higher. However, if you consider that the AC test voltage is an effective value, this is put into perspective. The peak value of the AC test voltage is the rms value times √2 – i.e. 1.41 times.

Test objects often have unavoidable capacitances due to filter capacitors or due to their physical construction.

The high-voltage test with AC then has the disadvantage that a high capacitive leakage current can flow through these capacities. However, this does not have to be a fault, since the physical construction of the test object naturally allows this leakage current to flow. In order to disregard the portion of the imaginary current through the test piece capacitance, high-voltage testers from SCHLEICH also have the option of differentiating between active and reactive current during the evaluation.

If, on the other hand, testing is carried out with DC, the capacitance only plays a subordinate role. After the capacitance has been charged, only a very small insulation current flows through the insulation resistance. Just like in a test with AC, this current must not exceed a specified limit. In addition, SCHLEICH high-voltage testers also determine the insulation resistance from the test voltage and the leakage current. In a high-voltage test with DC, the tester also becomes a megohmmeter.

How is the high-voltage test carried out?

Whether manual, partially or fully automatic: with high-voltage testers from SCHLEICH, every test task can be carried out quickly and efficiently.

Our testing devices are all designed according to the "KISS principle". So according to the motto: " Keep It Simple and Smart " . The principle is the leitmotif for all SCHLEICH products.

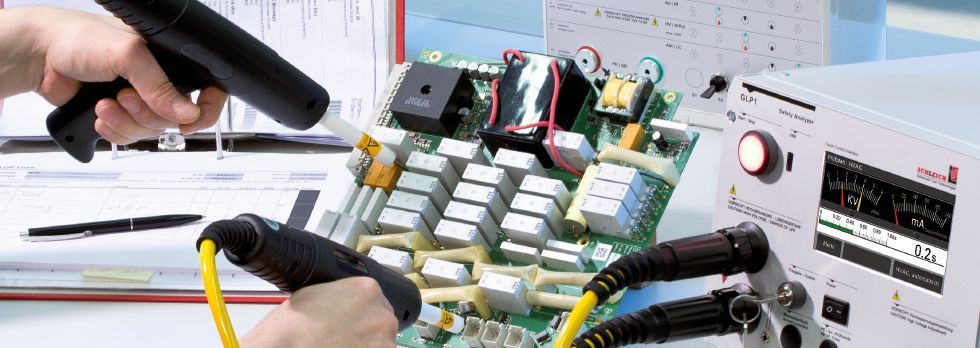

A manual test is carried out with high-voltage test guns. To do this, the operator guides the safety test pistols by hand from test point to test point. Despite the manual process, the test can be perfectly documented. A typical application here is the testing of electrical products, control cabinets and machines according to the Machinery Directive EN60204.

Partially or fully automated high-voltage test devices or high-voltage test machines are more suitable for the requirements of production companies. For this purpose, the test devices are equipped with a relay switch panel (relay matrix). This switching field automatically switches the high voltage to the desired test points.

Depending on the application, test systems of this type have up to 1,000 test connections.

Safe implementation of the high-voltage test.

Working with high voltage is not without risk. It is therefore essential to comply with the relevant safety regulations and measures to protect against accidental contact.

Protective measures can only be dispensed with if the current output of the high-voltage test device is limited to a maximum safety current. The safety current limitation limits the test current to max. 3 mA AC or max. 12 mA DC. However, such high-voltage test devices can only be used if the leakage current flowing even with a good test object is below the safety current limit. Many test objects such as electric motors naturally allow a capacitive leakage current of often well over 3 mA AC to flow. A safety current limitation cannot therefore be used with these test objects.

However, a second criterion must also be taken into account. Many test objects have an unavoidable capacity due to their construction. Capacitive leakage current flows in this capacity. Furthermore, the capacitance can also store charges. If this is the case, the maximum stored energy must not exceed 350 mJ (VDE 104 / EN 50191). Otherwise, there is a risk of electric shock for the operator when touching the test object due to the remaining charge.

If the safety current limitation is not possible, test hoods, test cabins, light curtains or shut-off chains are used as protective measures.

Potential-free high-voltage test?

In most applications, the potential-free high-voltage test is used. It is typical for use with safety test guns. It guarantees the highest level of safety for the user.

At higher high voltages from 15,000 V upwards, the high voltage is usually grounded on one side.

What do you have to consider during a high-voltage test?

In order to carry out the high-voltage test correctly, it must be ensured that the test object is actually connected to the high voltage. A correctly performed test is checked using three possible variants of contact monitoring:

- Specification of a minimum current - advantageous for test objects where a leakage current flows. If this minimum current flows, you can be sure that the test object is also live.

- With a DC test voltage, the leakage current is very low. Here, however, contact monitoring can be carried out by measuring the charging current at the beginning of the high-voltage test.

- Measurement of the voltage actually applied to the test object. For this purpose, two additional sense lines are connected to the test object in addition to the test lines. This type of measurement is often also called four-wire measurement. The high voltage actually applied to the test object is measured via the two sense lines. This voltage is compared to a default value. That's why we call this control procedure voltage back measurement.

Requirements for a standard high-voltage test device?

Many national and international standards prescribe a power of > 500 VA with a continuous current of 100 mA AC and a short-circuit current of 200 mA AC. Typical maximum test voltages are 3,000 or 6,000 V.

SCHLEICH high-voltage test devices are equipped with a fast-reacting electronic high-voltage source. This allows the precise sequential running of voltage profiles.

SCHLEICH high-voltage testers are based on more than 30 years of experience. From the beginning, the measurement technology was not analogue, but always digital. In principle, the latest technologies are always used.

How do you find the right high-voltage tester?

The number of high-voltage testers available on the market is large and the number of configurable features is overwhelming.

With a few basic considerations, however, you can easily find the right voltage tester.

If you only want to carry out high-voltage tests with AC or DC on your test object, you are well advised to use a single test device. It only contains a single test method, namely the high-voltage test.

If the test object also requires a more comprehensive safety and function check, we recommend our combination test devices/multifunction testers. This means that various test methods such as high-voltage, insulation and protective conductor resistance tests can be conveniently combined in one test device. The test method switching integrated in the test device ensures that no measuring lines on the test object have to be reconnected manually during the test.

In addition, there is often a combination of safety tests and extensive functional tests. For the function test, the test device also supplies the test object with electrical operating voltage in order to also check the electrical operating properties.

Thanks to the intuitive and convenient operation of our high-voltage testers, each test is quick, precise and cost-effective.

The SCHLEICH product portfolio

- Test voltage of 3000 V, 6000 V up to 120 KV AC/DC

- Power from 500 VA to 35 KVA

- With electronic, automatically regulated high voltage

- With integrated discharge and discharge monitoring

- Standardized interfaces such as RS 232, Ethernet / LAN, USB for PC communication

- 24 V digital I/O for PLC communication

- Expandable to Industrial Ethernet and fieldbus systems for PLC communication

- Almost unlimited storage space for test plans and test results

- All parameters are determined via the software

In addition, we are happy to plan, design and produce individually tailored solutions for you:

- Combination tests/Multifunction tests

- Testing machines/testing systems with a small to complex relay matrix

- Complete testing workstations

- Production lines with transfer systems

- EOL jobs

- large plants

When selecting your high-voltage test device, also pay attention to the "soft skills" of the provider. We offer all the necessary accessories and accompany you throughout the entire service life of your high-voltage tester:

- Professional advice with technical know-how

- Careful initial start-up

- Regular certified calibration

- After-sales support from our service team

- Service on the phone or on site

- Tailored training