Schleich Test Technologies

Leakage Current Testers

Everything you always wanted to know about leakage current testing.

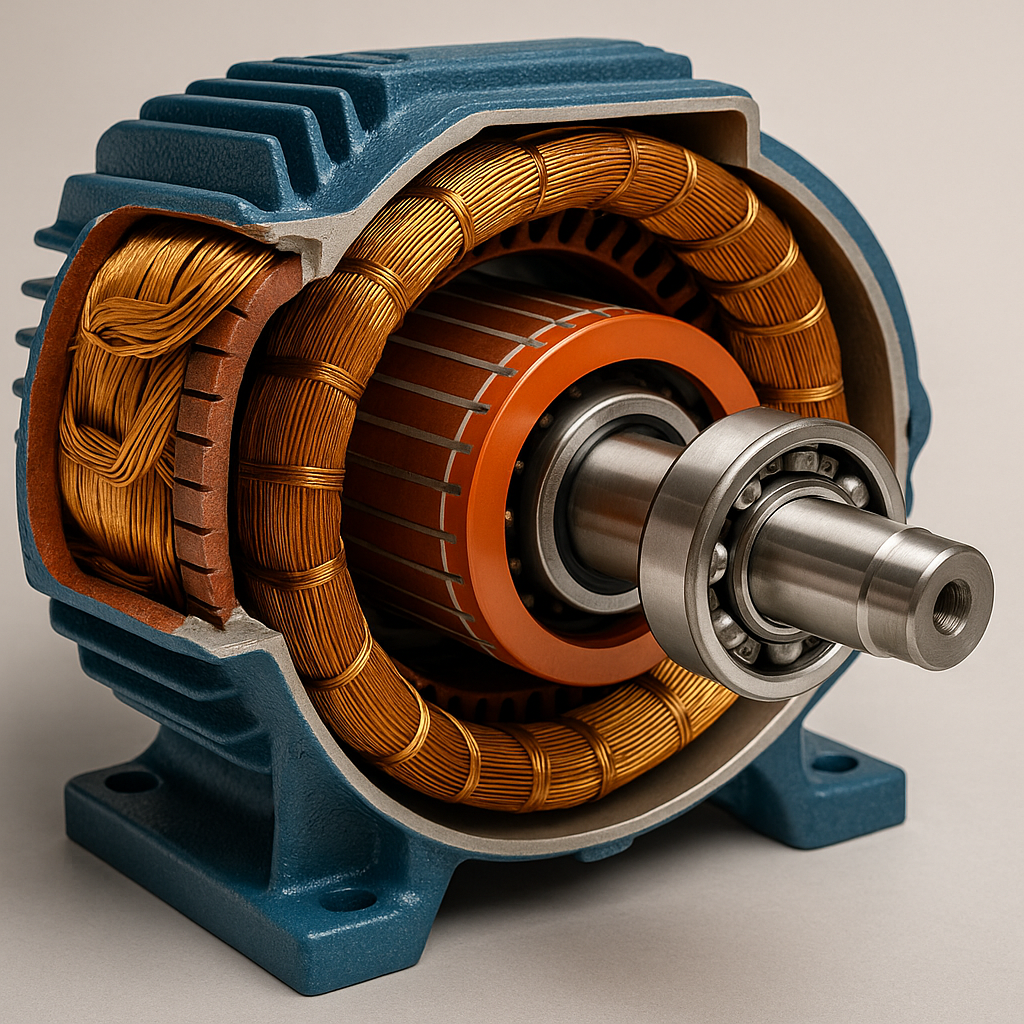

The leakage current test determines the magnitude of the current that flows from the current-carrying conductors to the protective conductor or to parts of the housing due to a weak insulation and/or due to the construction. Various test regulations (e.g. VDE, EN, IEC, UL ...) require the measurement and assessment of the leakage current.

Why is leakage current testing important?

Electrical products can only be operated safely if they have high electrical insulation strength.

In the worst case, poor insulation can lead to electrical accidents with serious injuries or death.

The electrical product is typically checked with a test voltage that is a percentage value specified in the standard above the nominal voltage of the electrical product. This value is often 1.1 times the nominal voltage.

What types of leakage current test are there?

The leakage current can be measured in two ways:

The test object is in function

- In the standard one speaks of procedure A

- This method is also called “warm leakage current test”

- The test voltage is fed in between the test object connections L and N

- There are two feed-in options:

- A1: L an Phase – Name Null

- A2: N an Phase – Lam Null

The test object is not working

- The standard refers to method B

- This method is also called “cold leakage current test”

- The test voltage is fed between the bridged test object connections L and N against the PE

What are the typical norms?

Two standards are of central importance in Europe worldwide:

EN60990

Methods for measuring touch current and protective conductor current

- Touch current on touchable metal parts of the test object

- Leakage current in the protective conductor of the test object

EN60601

Procedure for measuring leakage currents on medical products and systems

- Touch current on touchable metal parts of the test object

- Leakage current in the protective conductor of the test object

- Leakage current at patient connections etc.

- Various types of patient leakage currents under various fault conditions

- Various types of patient auxiliary flows under various fault conditions

- Measurement of the leakage current with frequency components up to 1 MHz

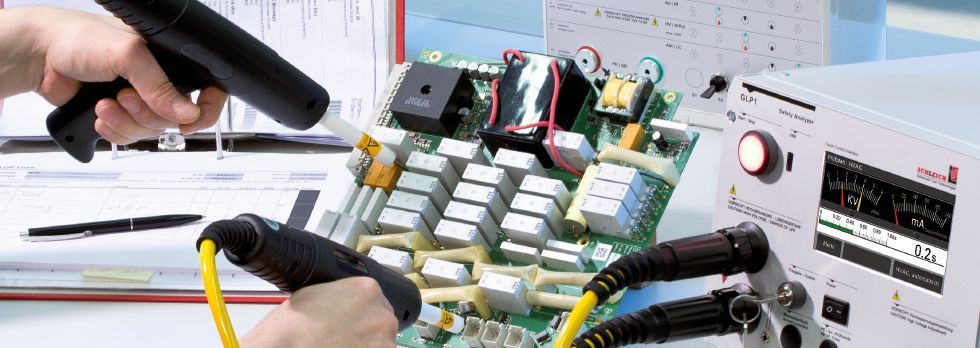

SCHLEICH has the appropriate testing devices for all European and global standards such as UL and their applications.

What are the “good/bad” criteria?

The assessment of the leakage current test is always based on the level of the current. It must not exceed an adjustable limit.

What are an MD?

The MD ( measuring device ) is a measuring circuit consisting of resistors and capacitors that is used to determine the leakage current .

In principle, it simulates the endangered person through whom the leakage current would flow in the event of damage.

Various different MD variants are listed in the standards. All of these variants can be integrated into a SCHLEICH leakage current test device.

What is the Substitute Leakage Current Test?

The substitute leakage current test is a cold leakage current test according to method B - but with a reduced test voltage of e.g. B. 40VAC. The current that flows when the test voltage is reduced is then extrapolated proportionally to the current that would flow at the nominal voltage x 1.1.

How do you find the right leakage current tester?

If you only want to carry out the leakage current test on your test object, you are well advised to use a single test device . However, it already contains two test methods, namely the functional test and the leakage current test.

The functional test is required in order to be able to operate the test object under voltage according to the A1/A2 procedure.

If the test object also requires a more comprehensive safety and function check, we recommend our combination test devices/multifunction testers . This means that various test methods such as insulation, high-voltage and protective conductor resistance tests can be conveniently combined in one test device. The test method switching integrated in the test device ensures that no measuring lines on the test object have to be reconnected manually during the test.

Thanks to the intuitive and convenient operation of our leakage current test devices, each test is quick, precise and cost-effective.

The SCHLEICH product portfolio

- Leakage current test according to EN60990

- Leakage current test according to EN60601 - medical leakage current test

- Measurement of the leakage current with all MD variants specified in the standards

- Measurement of leakage currents with a frequency of up to 1 MHz

- Standardized interfaces such as RS 232, Ethernet/LAN, USB for PC communication

- 24 V digital I/O for PLC communication

- Expandable to Industrial Ethernet and fieldbus systems for PLC communication

- Almost unlimited storage space for test plans and test results

- All parameters are determined via the software

In addition, we are happy to plan, design and produce individually tailored solutions for you:

- Combination tests/Multifunction tests

- Testing machines/testing systems with a small to complex relay matrix

- Complete testing workstations

- Production lines with transfer systems

- EOL Jobs

When selecting your leakage current test device, also pay attention to the “soft skills” of the provider. We offer all the necessary accessories and accompany you throughout the entire service life of your leakage current tester:

- Professional advice with technical know-how

- Careful initial start-up

- Regular certified calibration

- After-sales support from our service team

- Service on the phone or on site

- Tailored training