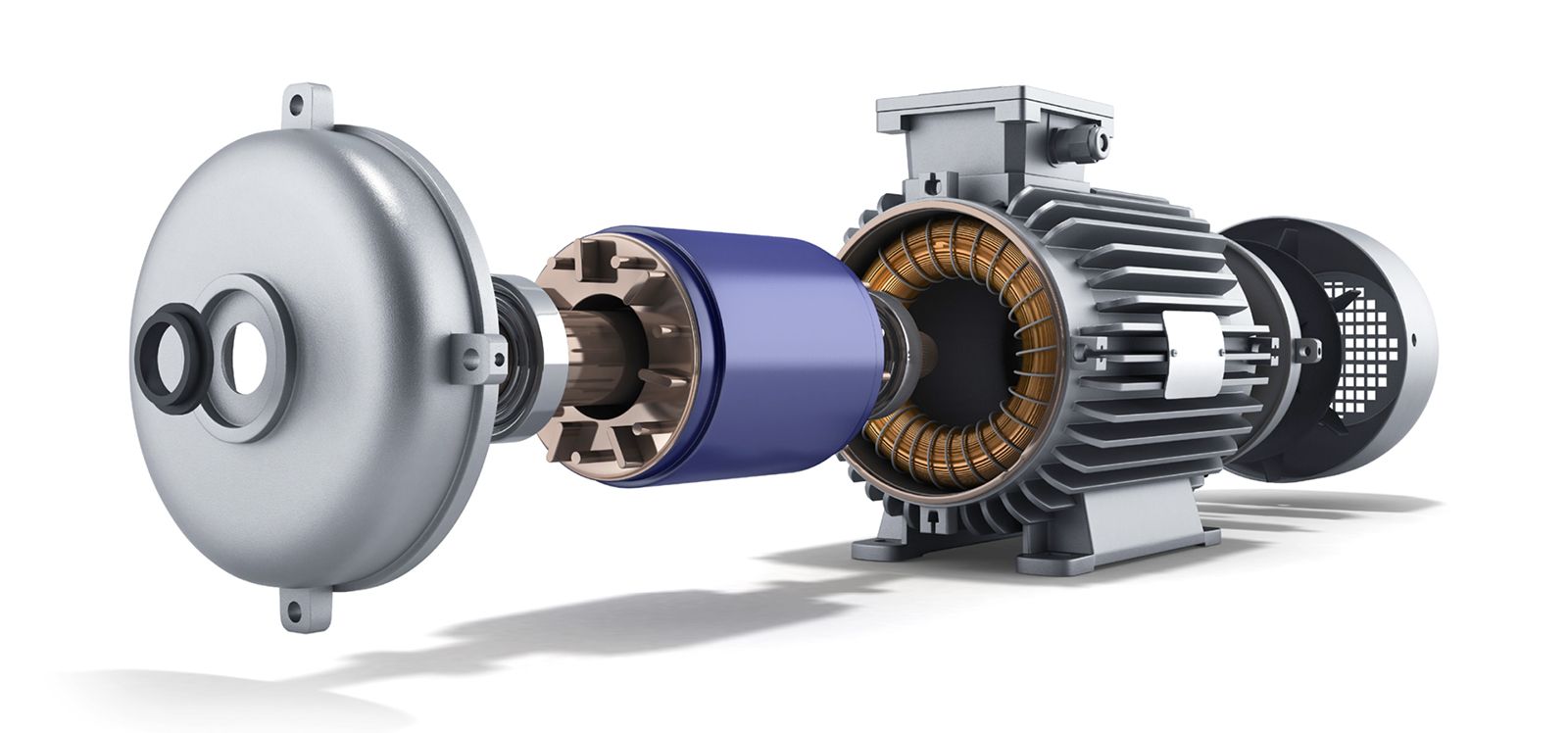

Induction Motor | Synchronous Motor | BLDC …

Testing technology for ALL types of electric machines.

Bearings

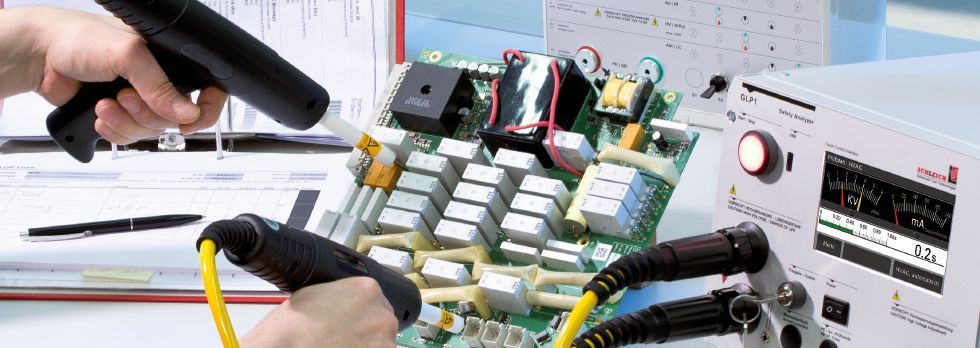

SCHLEICH supplies test systems for the intermediate and final inspection of electric motors for the entire motor production process.

From testing the entire motor to the winding, you receive all test methods for safety and quality testing from a single source.

Test Methods

- Vibration

- vibration

- Tension between rotor, bearing and end shield

- Engine assembly error

- balancing

- EOL

- and more

Mechanical Parameters

SCHLEICH offers test solutions for the intermediate and end of line inspection of electric motors for the entire motor production process.

You can choose from a variety of test methods for safety- and quality checks for checking entire motors down to individual windings.

Test methods

- no-load and load operation

- mechanical functionality and parameters

- temperature rise test

- continuous operation with load cycles

- sense of rotation

- torque

- rpm

- detent torque

- torque ripple

- including complete mechanical testing structures and adaption

- EOL

- and more

Rotor Quality

SCHLEICH offers test solutions for the intermediate and end of line inspection of electric motors for the entire motor production process.

Test methods

- rotor quality

- including complete mechanical testing structures and adaption

- EOL

- and more

Electrical Parameters

SCHLEICH offers test solutions for the intermediate and end of line inspection of electric motors for the entire motor production process.

You can choose from a variety of test methods for safety- and quality checks for checking entire motors down to individual windings.

Test methods

- winding resistance

- winding inductances

- capacitance

- PE/GB resistance

- insulation resistance

- insulation resistance hot

- high-voltage AC

- high-voltage AC hot

- leakage current

- high-voltage DC

- high-voltage DC hot

- electrical functionality and parameters

- cos ϕ

- active-, apparent-, reactive-power

- short-circuit current test Uk

- no-load and load operation

- temperature rise test

- continuous operation with load cycles

- testing of all components including:

- motor brake

- heating system

- temperature sensor

- encoder, resolver, transmitters of all kinds …

- offset angle adjustment of the encoder

- reading and writing the electronic type plate

- including complete mechanical testing structures and adaption

- EOL

- and more

Turn-to-Turn Fault, Fault-to-Frame, Phase-to-Phase Fault

SCHLEICH offers testing solutions for every step of the production of electric machines.

From testing copper wires to professional winding testing to the entire motor …

A wide range of test methods for quality and safety testing is available.

Winding tests

- surge voltage up to 50 kV

- partial discharge on surge voltage

- high-voltage AC

- partial discharge on high voltage

- leakage current

- high-voltage DC

- insulation resistance

- DAR – dielectric absorption ratio

- PI – polarization index

- and more

SCHLEICH has been a pioneer in the field of winding testing for more than 35 years. Countless innovative products and services are what distinguishes us from our competitors. Thousands of winding testers for satisfied customers all over the world are testimony to our success.

Motor Test Plug

SCHLEICH offers a wide range of motor test plugs / testing adaptors for various contactings and requirements.

Contacting solutions adapted to the e-machine

- 3-pole motor test plugs forvarious sizes of terminal boards and bolt diameters

- 6-pole motor test plugs forvarious sizes of terminal boards and bolt diameters

- 9-pole motor test plugs forvarious sizes of terminal boards and bolt diameters

- motor test plugs with one or two leading grounding tips for contacting the mounting screw

- motor test plug in 2- or 4-wire technology

- test plugs for luster terminals

- Kelvin clips,in block, freely customizable

- Kelvin clips, loose

- made-to-order solutions

- fully automated contacting solutions

- and more

All test plugs and test clips are designed and made at our facilities in Hemer. We also offer fully pre-wired sets.

We can deliver most test systems including mechanical parts and test plugs as a turn-key solution, providing you with a single point of support for all your requirements.

Cable, Feeder

SCHLEICH offers test solutions for every step of the production of electric machines.

A wide range of test methods for quality and safety testing is available.

Testing the feeder

- PE/GB-resistance – Consideration of cable lengths and cross-sections

- polarity resistance

- ohmic resistance

- high-voltage AC

- leakage current

- high-voltage DC

- insulation resistance

- DAR – dielectric absorption ratio

- and more

Type Plate, Traceability

SCHLEICH offers testing solutions for every step of the production of electric machines.

We offer a wide range of solutions for labeling and marking.

Traceability solutions

- label printing

- laser printing

- marking with special dot matrix printing

- RFID-marking

- electronic type plates

- 1- or 2D-barcodes

- reading and writing the electronic type plate

- and more

Motor Brake

SCHLEICH offers testing solutions for every step of the production of electric machines.

We offer a wide range of solutions for controlling and testing of attached parts.

Testing of brake, clutch and heating

- automated variation of brake power supply AC/DC

- bedding in of brakes

- automated measurement of holding torque

- holding torque measurement with torque limiting spanner

- automated measurement of braking torque

- automated variation of heating supply

- and more

Encoder – Angle Adjustment

SCHLEICH offers test solutions for the intermediate and end of line inspection of electric motors for the entire motor production process.

You can choose from a variety of test methods for safety- and quality checks for checking entire motors down to individual windings.

Test methods

- resolver test including resolver power supply

- resolver angle adjustment

- encoder test including encoder power supply

- encoder angle adjustment – zero track / Z-pulse

- absolute value encoder including encoder power supply

- HIPERFACE

- HIPERFACE DSL

- EnDat

- SSi

- BiSS

- single- and multi-turn encoder

- angle offset stored in the encoder

- storage of additional information in the encoder

- BEMF-measurement

- ke-measurement and normalization to V/1000 RPM or V/Hz

- EOL

- and more

SCHLEICH is at your side. Whether you are looking for a “basic” no-load test stand or a large-scale load test stand that includes a wide range of attachments.

Many manufacturers of standardized and specialty motors worldwide rely on our testing technology. In addition to reliable testing technology and MES data exchange (Manufacturing Execution System), the international networking of testing and database systems, such as SAP®, is becoming increasingly important. From laboratory testing equipment for research and development to fully automated testing systems, SCHLEICH is your one-stop shop.

All key aspects of expertise remain in the hands of SCHLEICH.

Our test systems are not created by simply combining off-the-shelf standard components. Each individual part is SCHLEICH know-how and is developed and manufactured in Hemer by our own team of experts.

Test devices and test systems

GLP3 | Class-leading testing technology unlimited.

The TOP class of testing and measuring technology for safety and functional testing.

- „All in one”

- Safety & functional testing devices

- For complex projects

- For complex automation

- For the highest demands

- Can be combined modularly from over 30 test methods

- Up to 350 test connections

- Switch matrices for all types of test methods

- PLe, SIL3, Cat4 safety circuit

- Windows 10®

- network

- Protocol & label printing

- Industry 4.0

- Interfaces to MES, ERP, SPS …

GLP3-M | Electric motor testing - EOL, series and laboratory

Test benches for functional and safety testing of all types of engines.

- asynchronous motors

- synchronous motors

- stepper motors

- BLDC

- DC motors…

- engine attachments

- Brake

- temperature sensor

- additional heating

- Ventilator

- Encoder, Resolver, Multiturngeber …

- Interfaces for automation such as PROFINET, EtherCAT, TCP/IP ...

- Interfaces to various ERP and MES systems ...