Lights | light technology

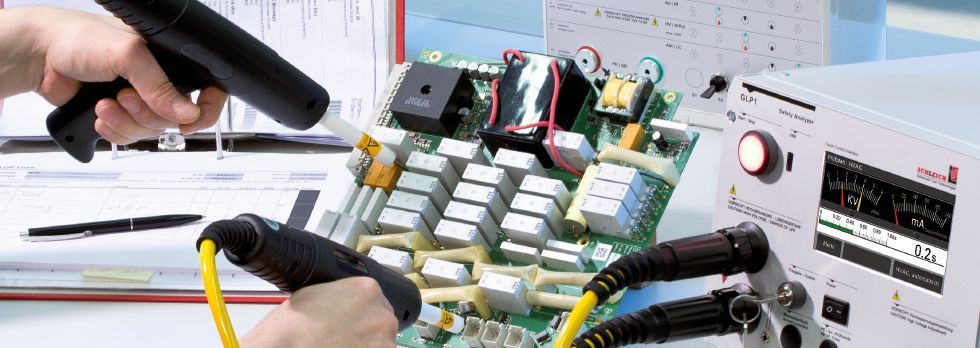

Testing technology for all types of lights.

PE/GB Testing

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires of a wide variety of types for the entire production process of the devices.

Test methods

- PE/GB, PE/GB-resistance

- test currents from 10 A to 30 A

- PE/GB-test probes with 4-wire measurement

- automatic switch-over between multiple PE test spots

- temperature test

- continuous operation

- compact PE/GB-resistance testers

- multitesters containing a combination of all essential test methods

- including complete mechanical testing structures and adaption

- and more

From single safety test devices to a large-scale test stand including a wide range of attachments, SCHLEICH is your one-stop-shop.

Many manufacturers of lights and luminaires worldwide rely on our testing technology.

Test Plug

SCHLEICH offers test plugs for mains connections, light components, modules, printed circuit boards (PCBs), stranded wires and sockets for various types of designs and intended ranges of application.

Contactings fitting the luminaire

- test plug with pins for luster terminals

- 3-, 4-, 5-, 6- and 7-pole test plug with pins/socket connector for mains connection with or without communication interface for any designs and types of construction

- test plug with pins/socket connector for connecting terminals of a looped-in wiring

- test plug for LED lights

- test plug for conventional luminaires

such as: fluorescent lamps, compact fluorescent lamps, discharge lamps, halogen lamps (low voltage and high voltage), incandescent lamps … - custom solutions

- fully automated custom contactings for production lines

- and more …

All test plugs and test adaptors are designed and made at our facilities in Hemer. We also offer fully pre-wired sets. We can deliver most test systems including mechanical parts and test plugs as a turn-key solution, providing you with a single point of support for all your requirements.

Function and Safety Testing

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices. From testing the complete luminaire down to testing single LED modules, SCHLEICH is your one-stop shop for a variety of test methods for safety- and quality checks.

Test methods

- PE/GB, PE/GB-resistance

- insulation resistance

- high voltage AC

- high voltage DC

- electric function

- leakage current

- temperature test

- continuous operation with different load profiles

- including complete mechanical testing structures and adaption

- and more

From single safety test devices to a large-scale test stand including a wide range of attachments such as cameras and robotic support, SCHLEICH is at your side.

Many manufacturers of lights and luminaries worldwide rely on our testing technology.

Testing the Dimming Functionality

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaries for the entire production process of the devices. There is a growing trend to dimming luminaires to save energy, employing a wide variety of technologies. To test all types of dimming technologies, we have developed an exclusive universal interface. This interface is used to test dimmer cabling, cable polarity reversal, dimmer functionality and to parameterize modern luminaires. Furthermore, after a test is completed, additional information can be stored in the ECG. quality checks.

Test methods

- dimming the luminaire

- parameterization of the ECG

- DALI

- Casambi

- HUE

- DMX

- DSI

- analogue dimming input 0 (1) to 10 V

- various types of touch dimmers (“Touch DIM”)

- can be combined with insulation and high voltage testing

- and more

Inspection of Optical Components

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices.

There is a growing trend to fit modern luminaires with a wide range of additional complex optical components.

A number of different aspects must be controlled during inspection:

- have the right components been fitted?

- have the components been mounted in the correct position?

- are all components functional?

- and more

These tests can be conducted as visual inspections.

Two ways of visual inspection are possible:

- human visual inspection – conducted by the operator

- fully automated visual inspection – using one or several cameras

Test methods and tasks

- human visual inspection including qualitative assessment (GO/NOGO)

- human visual inspection including quantitative assessment

- automated optical inspection by cameras

- integration of cameras from a variety of suppliers

- lighting of the test environment

Wiring Testing

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices.

Today, practically all luminaires are equipped with LEDs. In most cases, no sockets are used for the LEDs. Instead, LED units are connected directly to the output terminals of the electronic control gear (ECG) via direct wiring.

In addition, the ECGs between the input-side mains supply and the output-side LED control are galvanically isolated. As a result, the wiring behind the ECGs is practically no longer accessible for insulation tests.

However, the wiring must be inspected in relation to the voltage of the LED power supply.

These tests can be conducted as visual inspections.

Two ways of visual inspection are possible:

- human visual inspection – conducted by the operator

- fully automated visual inspection – using one or several cameras

Test methods and tasks

- human visual inspection including qualitative assessment (GO/NOGO)

- automatic optical inspection by cameras

- integration of cameras from a variety of suppliers

- lighting of the test environment

- through-wiring typically up to 7 wires, PE-N-L1-L2-L3-DA1-DA2

- through-wiring for built-in sockets

- through-wiring for built-in switches

- fully automated through-wiring/polarity reversal testing

- manual or automated test of phasing

- PE/GB-testing with norm-conforming test currents from 10 to 30 A AC/DC

- insulation resistance tests between the conductors and to PE/GB up to 1,000 V DC

- high voltage tests between the conductors and to PE/GB up to 3,000/6,000 V AC/DC

- custom solutions

- and more

From single safety test devices to a large-scale test stand including a wide range of attachments, SCHLEICH is your one-stop-shop.

Many manufacturers of lights and luminaires worldwide rely on our testing technology.

Screw Torque

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaries for the entire production process of the devices. In a fully automated luminaire production, many components are placed and screw-fixed automatically. The screwdriving process must be executed reliably with a given force.

Consequently, automatic screwdrivers with torque sensing are frequently employed.

Test methods and tasks

- automated optical screw torque monitoring

- fully developed communication interfaces to automatic screwdrivers from various manufactures

From single safety test devices to a large-scale test stand including a wide range of attachments, SCHLEICH is your one-stop-shop.

Many manufacturers of lights and luminaires worldwide rely on our testing technology. In addition to reliable testing technology and MES data exchange (Manufacturing Execution System), the international networking of testing and database systems, such as SAP®, is becoming increasingly important.

Parameterization of the Electronic Control Gear

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices.

A modern intelligent electronic control gear (ECG) is required to address the LED module. ECGs are used for dimming, for proper control of the LED current, for optimizing the brightness characteristics curve while dimming and for color control (RGB). To minimize costs, luminaire manufacturers often use only a limited set of ECG models. However, the variety of LED modules is enormous and technical characteristics can differ greatly. The same ECG can therefore be used with a great range of LED modules. Various settings can be transferred to the ECG via interface for this purpose. This process is called parameterization. To transmit parameters, a DALI interface is used frequently. Luminaires without a hardware interface can be parameterized via the power grid, via an additional parameterization connector or over the air

via NFC (Near Field Communication).

Tasks

- parameterization of ECGs

- via DALI

- via NFC, over the air

- via power grid

- via parameterization connector

- via custom solutions

- transmission of individual parameters

- transmission of manufacturer-specific parameter files

- and more

Brightness

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices.

The overwhelming number of luminaires today are fitted with LEDs.

To achieve a light surface that appears as uniform as possible to the onlooker, many LEDs are interconnected to form LED clusters on a printed circuit board. The brightness of the individual LEDs must be within a narrow tolerance for this purpose. This applies to both full output and dimmed modes.

Necessary tests can be conducted as visual inspections.

Two ways of visual inspections are possible:

- human visual inspection – conducted by the operator

- fully automated visual inspection – using cameras

However, human visual inspection can only be used in simple test configurations, as the brightness of the LEDs can be quite intense. Furthermore, the number of LEDs to be inspected can also potentially be very high. In many cases, human visual inspection cannot meet the requirements of sophisticated test scenarios.

Brightness can be determined much more precisely with cameras equipped with special lenses and apertures.

Often the light color is also determined simultaneously to brightness measurements.

For more information, please contact us.

Test methods and tasks

- automatic optical inspection by cameras

- integration of cameras from a variety of suppliers

From single safety test devices to a large-scale test stand including a wide range of attachments, SCHLEICH is your one-stop-shop.

Many manufacturers of lights and luminaries worldwide rely on our testing technology. In addition to reliable testing technology and MES data exchange (Manufacturing Execution System), the international networking of testing and database systems, such as SAP®, is becoming increasingly important.

LED Modules

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires of a wide variety of types for the entire production process of the devices. Luminaire manufacturers either produce their LED modules themselves or source them from other suppliers. These LED modules must be tested or subjected to an incoming goods inspection before they are fitted into the luminaire. Similarly, LED modules to be supplied to OEMs must be tested. A DC function test, for example, is used for this purpose. Specified test currents can be fed into an LED or into the LED modules to this end.

Test methods

- DC power supply

- functional test with a constant current

- testing brightness

- testing luminous color

- custom solutions

- including complete mechanical testing structures and adaption

- and more

From single safety test devices to a large-scale test stand including a wide range of attachments such as cameras and robotic support, SCHLEICH is at your side.

Many manufacturers of lights and luminaires worldwide rely on our testing technology.

Luminous Color

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices.

The overwhelming number of luminaires today are fitted with LEDs.

To achieve a light surface that appears as uniform as possible to the onlooker, many LEDs are interconnected to form LED clusters on a printed circuit board. The luminous colors of individual LEDs must be within a narrow tolerance for this purpose.

In many cases LEDs on an LED array are additionally fitted in a prescribed layout, which also must be monitored carefully.

These tests can be conducted as visual inspections.

Two ways of visual inspection are possible:

- human visual inspection – conducted by the operator

- fully automated visual inspection – using one or several cameras

However, human visual inspection can only be used in simple test configurations, as the brightness of the LEDs can be quite intense. Furthermore, the number of LEDs to be inspected can also potentially be very high. Consequently, automatic test methods are typically the method of choice.

Cameras equipped with special lenses and apertures also measure the luminous color significantly more precisely.

Test methods and tasks

- automatic optical inspection by cameras

- integration of cameras from a variety of suppliers

From single safety test devices to a large-scale test stand including a wide range of attachments, SCHLEICH is your one-stop-shop.

Many manufacturers of lights and luminaires worldwide rely on our testing technology.

Insulation Testing

SCHLEICH offers test solutions for intermediate and end of line inspection of lights and luminaires for the entire production process of the devices.

Today practically all luminaires are equipped with LEDs. In most cases, no sockets are used for the LEDs, instead the LED units are connected directly to the output terminals of the electronic control gear (ECG) via direct wiring. In addition, the ECGs between the input-side mains supply and the output-side LED control are galvanically isolated. As a result, the wiring behind the ECGs is practically no longer accessible for insulation tests. However, the wiring must be inspected in relation to the voltage of the LED power supply. If the wiring is accessible by electrical means, an insulation test is used.

Test methods

- insulation, insulation resistance

- typical test voltage of 500 V DC, variable from 30 to 1,000 V DC

- PE/GB-test probe can also be employed for measurements at insulation test spots

- high voltage testing with AC or DC

- typical test voltages of 1,000 V AC, variable from 50 to 6,000 V AC or DC

- high voltage test probes

- compact PE/GB-resistance testers

- compact high voltage testers – the smallest high voltage tester with 500 VA in the world.

- multitesters containing a combination of all essential test methods

- including complete mechanical testing structures and adaption

- and more

Motor Diagnostic Systems is at your side. Whether you are looking for a “basic” no-load test stand or a large-scale load test stand that includes a wide range of attachments. Many manufacturers of standardized and specialty motors worldwide rely on our testing technology. In addition to reliable testing technology and MES data exchange (Manufacturing Execution System), the international networking of testing and database systems, such as SAP®, is becoming increasingly important. From laboratory testing equipment for research and development to fully automated testing systems, Motor Diagnostic Systems is your one-stop shop.

All key aspects of expertise remain in the hands of SCHLEICH.

Our test systems are not created by simply combining off-the-shelf standard components. Each individual part is SCHLEICH know-how and is developed and manufactured in Hemer by our own team of experts.